|

|

|

| You are here: Home> Products > Gate |

|

|

|

|

|

| Product Name:Weld globe valve |

| Product Classification:Globe valve |

| Product Introduction: |

J61H, J61Y type PN200 ~ PN320 power plant valve butt welding high temperature for nominal pressure PN200 ~ PN320 and P54/100V-P57/170V, working temperature ≤ 540 ℃ (which P57/170V operating temperature of 570 ℃) of the petroleum, chemical, water, fire station in a variety of system piping, cut off or connect line media. |

|

| Description |

Parameters |

Size Chart |

Application |

|

【Features】

1, the valve chamber seal by pressure from the tight structure, sealing performance, the better. Branch pipe at both ends of welded structures. Welding groove can be connected with standard or user requirements

2, valve, valve seat sealing surface using cobalt-based alloy stellite surfacing made ??of wear-resistant, high temperature, anti-abrasion performance and long service life

3, the stem after the quenching and surface nitriding, has good corrosion resistance and scratch resistance out.

4, valve cover reasonable depth of stuffing, packing plus inhibitor, reliable sealing

[Executive standard]

Design standard: JB / T 3595/E101

Structure length: JIS E101

Butt end: ANSI B16.25

Test and inspection: JIS E101

Pressure - Temperature: JB / T 3595

Product ID: GB / T 12220

Supply specification: JIS E101 |

|

[Performance parameters]

|

Model |

J61H-200V |

J41Y-200V |

|

Working pressure(MPa) |

19.6 |

15.58 |

6.96 |

19.6 |

15.58 |

6.96 |

|

Temperature(℃) |

≤200 |

≤450 |

≤570 |

≤200 |

≤450 |

≤570 |

|

Medium |

Water.steam,ect |

|

Material |

Valve Body ,bonnet |

Chrome-molybdenum vanadium steel

|

|

Valve disc |

Chrome-molybdenum vanadium steel+hard facing alloy |

|

Seat |

Chrome-molybdenum vanadium steel+hard facing alloy |

|

Valve stem |

Chrome-molybdenum vanadium steel |

|

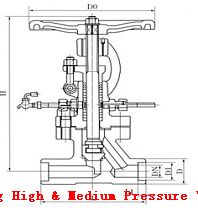

產品外形及結構尺寸示意圖

|

working principal:Valve is forced closed valve, so the valve is closed, the valve must exert pressure to force the sealing surface does not leak. When the media from the valve into the valve below the six o'clock, the operating force required to overcome the resistance, is the stem and packing friction and pressure from the media generated by the thrust force than the valve off the valve opening force, Therefore, the diameter of the stem to a large, otherwise the top stem bending failure occurs. In recent years, the emergence of self-sealing valve, globe valve replaced by medium flow valve on the top into the valve chamber, then in the medium under pressure, the valve off a small force, and force open the valve, stem diameter may be reduced accordingly. Meanwhile, in the medium under the action of this form of valve is also more closely. China Valves "three to" has been provided, the flow valve, all top-down.

Note: 1.hand wheel, lever operated valves can be installed in any position in the pipeline.

2 hand wheels, handles and Wei moving body does not allow for lifting purposes.

3 medium as shown in the flow direction of the arrow should be consistent with the body.

|

|